The future prospects of laser cleaning technology

18 min read

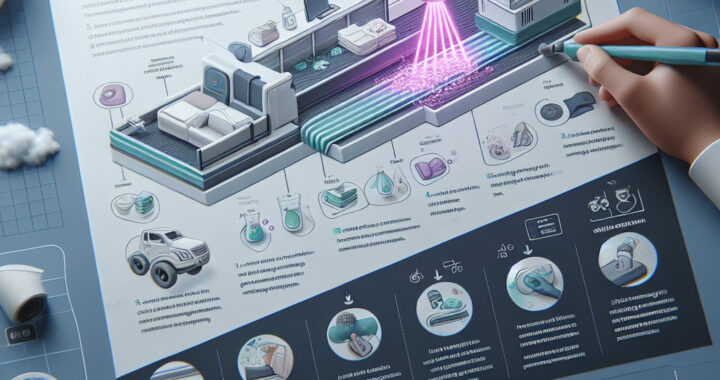

- The history and development of laser cleaning technology

- The applications of laser cleaning in various industries

- The environmental benefits of laser cleaning technology

- The potential for laser cleaning to replace traditional cleaning methods in the automotive industry

- The role of laser cleaning in the maintenance and preservation of infrastructure

- The integration of laser cleaning technology into robotic systems

- The role of laser cleaning in the removal of contaminants from electronic components

- The potential for laser cleaning to reduce the risk of cross-contamination in the healthcare sector

The history and development of laser cleaning technology

The concept of using lasers for cleaning purposes dates back to the 1960s when researchers began experimenting with laser beams to remove contaminants from surfaces. However, it wasn’t until the 1980s that laser cleaning technology started gaining significant attention and development.

One of the earliest applications of laser cleaning technology was in the restoration of artworks and historical artifacts. Traditional cleaning methods often involved the use of harsh chemicals and mechanical abrasion, which posed a risk of damaging the delicate surfaces. Laser cleaning offered a non-contact and precise method of removing dirt and grime without causing any harm to the underlying material.

As the technology advanced, laser cleaning found its way into various industries, including automotive, aerospace, electronics, and manufacturing. The ability of lasers to remove rust, paint, and other coatings from metal surfaces made it an ideal solution for restoring old machinery and equipment. Laser cleaning also proved to be effective in removing contaminants from electronic components without causing any damage.

The development of laser cleaning technology was driven by advancements in laser technology itself. The introduction of high-power lasers, such as fiber lasers and pulsed lasers, allowed for faster and more efficient cleaning processes. These lasers could deliver precise and controlled energy to the surface, ensuring thorough cleaning without causing any thermal damage.

One of the key advantages of laser cleaning technology is its non-abrasive nature. Unlike traditional cleaning methods that involve scraping or sandblasting, lasers do not physically touch the surface being cleaned. This eliminates the risk of surface damage and ensures a gentle yet effective cleaning process. Laser cleaning is also a dry process, meaning it does not require the use of water or chemicals, making it environmentally friendly.

Another advantage of laser cleaning technology is its versatility. Laser systems can be adjusted to different power levels, pulse durations, and wavelengths, allowing for customization based on the specific cleaning requirements. This flexibility makes laser cleaning suitable for a wide range of applications, from delicate artworks to heavy industrial machinery.

In recent years, laser cleaning technology has continued to evolve. Researchers are exploring new laser sources and techniques to further enhance the cleaning capabilities. For example, ultrafast lasers are being used to remove contaminants at the molecular level, providing a more thorough and precise cleaning process.

The future prospects of laser cleaning technology are promising. As the technology becomes more affordable and accessible, we can expect to see its widespread adoption across various industries. Laser cleaning has the potential to replace traditional cleaning methods, offering a safer, more efficient, and environmentally friendly solution.

Keywords: laser cleaning technology, history, development, applications, advantages, future prospects.

Long-tail phrases:

1. Laser cleaning technology for delicate artifacts.

2. Advancements in laser technology for efficient cleaning.

3. Non-abrasive and environmentally friendly laser cleaning.

4. Versatility of laser cleaning for various applications.

5. Ultrafast lasers for molecular-level cleaning.

6. The potential of laser cleaning technology in different industries.

The applications of laser cleaning in various industries

In the aerospace industry, laser cleaning plays a crucial role in maintaining the integrity of aircraft components. The removal of contaminants, such as grease, oil, and carbon deposits, from engine parts and turbine blades is essential for ensuring optimal performance and fuel efficiency. Laser cleaning also helps in the inspection and maintenance of critical aerospace components, such as landing gears and hydraulic systems, by providing a clean surface for accurate testing and analysis.

The electronics industry also benefits greatly from laser cleaning technology. The removal of oxides, flux residues, and other contaminants from electronic components, such as circuit boards and connectors, ensures reliable and efficient operation. Laser cleaning is particularly useful in the production of microelectronics, where precision and cleanliness are of utmost importance. By eliminating impurities, laser cleaning helps in improving the yield and quality of electronic devices.

In the healthcare sector, laser cleaning finds applications in medical device manufacturing and maintenance. Surgical instruments, implants, and other medical equipment require stringent cleanliness standards to prevent infections and ensure patient safety. Laser cleaning provides a non-destructive and efficient method for removing biofilms, organic residues, and other contaminants from these critical medical devices. Moreover, laser cleaning is also used in the restoration and preservation of historical artifacts and artworks, where traditional cleaning methods may cause damage.

The applications of laser cleaning extend to the energy sector as well. In power plants, laser cleaning is used to remove fouling and deposits from heat exchangers, boilers, and condensers, improving their efficiency and reducing maintenance costs. Solar panels, which often accumulate dust and dirt, can also benefit from laser cleaning, as it ensures maximum energy absorption and output. Furthermore, laser cleaning is employed in the maintenance and cleaning of wind turbine blades, enhancing their performance and prolonging their lifespan.

In summary, laser cleaning has become an indispensable tool in various industries, offering numerous benefits such as improved efficiency, reduced maintenance costs, and enhanced product quality. The automotive, aerospace, electronics, healthcare, and energy sectors are just a few examples of industries that have embraced this technology. As laser cleaning continues to evolve and advance, its applications are expected to expand further, revolutionizing the way we clean and maintain various surfaces.

Keywords: laser cleaning, industries, automotive, aerospace, electronics, healthcare, energy, contaminants, maintenance, efficiency, surface.

Long-tail phrases: laser cleaning in automotive industry, laser cleaning in aerospace industry, laser cleaning in electronics industry, laser cleaning in healthcare sector, laser cleaning in energy sector, benefits of laser cleaning, applications of laser cleaning technology, non-contact cleaning method, removal of contaminants, improved efficiency, reduced maintenance costs, enhanced product quality.

The environmental benefits of laser cleaning technology

Furthermore, laser cleaning technology is a highly efficient and precise method, resulting in minimal waste generation. Unlike traditional cleaning methods that often involve the use of disposable materials such as wipes, brushes, or sandblasting media, laser cleaning produces no physical waste. The laser beam directly targets the contaminants, vaporizing them into the atmosphere without leaving behind any residue or by-products. This not only reduces the amount of waste generated but also eliminates the need for disposal and the associated environmental impact.

In addition to its waste reduction capabilities, laser cleaning technology also minimizes energy consumption. Traditional cleaning methods often require the use of heavy machinery or equipment that consumes significant amounts of energy. Laser cleaning, on the other hand, utilizes focused laser beams that require minimal power to operate. This energy efficiency not only reduces the carbon footprint but also contributes to cost savings for industries and individuals.

Another environmental benefit of laser cleaning technology is its versatility and adaptability. It can be used on a wide range of surfaces, including metals, plastics, ceramics, and even delicate materials such as artwork or historical artifacts. This versatility eliminates the need for multiple cleaning methods, reducing the overall environmental impact associated with various cleaning techniques. Additionally, laser cleaning technology can be used in situ, meaning that objects or structures do not need to be transported to a separate cleaning facility, further reducing transportation-related emissions.

The long-term environmental benefits of laser cleaning technology are also worth mentioning. By eliminating the use of harmful chemicals and reducing waste generation, this technology contributes to the preservation of natural resources and ecosystems. It helps prevent pollution of water bodies, soil degradation, and air pollution, ensuring a sustainable future for generations to come.

In conclusion, laser cleaning technology offers numerous environmental benefits that make it a superior choice for surface cleaning and restoration. Its ability to eliminate toxic chemicals, minimize waste generation, reduce energy consumption, and adapt to various surfaces makes it an eco-friendly alternative to traditional cleaning methods. The long-term environmental advantages of laser cleaning technology contribute to the preservation of natural resources and the creation of a sustainable future. Embracing this innovative technology is not only beneficial for industries but also for the overall well-being of our planet.

Keywords: laser cleaning technology, environmental benefits, toxic chemicals, waste reduction, energy efficiency, versatility, adaptability, long-term sustainability.

Long-tail phrases:

– Laser cleaning technology: an eco-friendly alternative to traditional cleaning methods.

– The environmental advantages of laser cleaning technology in surface restoration.

– Reducing waste generation and energy consumption with laser cleaning technology.

– The long-term sustainability of laser cleaning technology in preserving natural resources.

The potential for laser cleaning to replace traditional cleaning methods in the automotive industry

Laser cleaning is a non-contact, non-abrasive method that uses high-intensity laser beams to remove contaminants from surfaces. This technology offers several advantages over traditional cleaning methods. Firstly, laser cleaning is a dry process, eliminating the need for chemical solvents or water, thus reducing waste and environmental impact. Secondly, laser cleaning is highly precise, allowing for selective removal of contaminants without damaging the underlying material. This is particularly important in the automotive industry, where delicate parts and sensitive surfaces need to be cleaned without compromising their integrity. Additionally, laser cleaning is a fast and efficient process, reducing cleaning time and increasing overall productivity.

Applications in the automotive industry:

The automotive industry encompasses a wide range of components and materials that require cleaning throughout the manufacturing process. Laser cleaning has proven to be effective in various applications, including the removal of paint, rust, grease, and other contaminants from metal surfaces. It can be used to clean engine parts, brake components, fuel injectors, and even the car body itself. Laser cleaning can also be applied to remove adhesives, coatings, and residues from glass, plastic, and composite materials. The versatility of laser cleaning makes it a valuable tool in maintaining the quality and performance of automotive parts.

Challenges and limitations:

While laser cleaning offers numerous benefits, it is not without its challenges and limitations. One of the main challenges is the initial investment cost. Laser cleaning systems can be expensive to acquire and maintain, making it a significant investment for automotive manufacturers. Additionally, the effectiveness of laser cleaning can be influenced by factors such as the type and thickness of the contaminant, the material being cleaned, and the surface geometry. Therefore, extensive testing and optimization are required to ensure optimal cleaning results. Furthermore, laser cleaning may not be suitable for all types of contaminants or materials, requiring alternative cleaning methods to be used in certain cases.

Conclusion:

Laser cleaning has the potential to revolutionize the cleaning process in the automotive industry. Its numerous benefits, including environmental friendliness, precision, and efficiency, make it an attractive alternative to traditional cleaning methods. While there are challenges and limitations to overcome, ongoing research and development in laser cleaning technology are likely to address these issues and further enhance its capabilities. As the automotive industry continues to strive for improved efficiency and sustainability, laser cleaning is poised to play a significant role in achieving these goals.

Keywords: laser cleaning, automotive industry, traditional cleaning methods, efficiency, precision, environmental impact, contaminants, materials, challenges, limitations, research and development.

Long-tail phrases: potential for laser cleaning to replace traditional cleaning methods in the automotive industry, advantages of laser cleaning over traditional methods, applications of laser cleaning in automotive manufacturing, challenges and limitations of laser cleaning in the automotive industry, future prospects of laser cleaning in the automotive sector.

The role of laser cleaning in the maintenance and preservation of infrastructure

Laser cleaning is a non-contact, non-abrasive, and environmentally friendly method of removing contaminants and unwanted substances from surfaces. It involves the use of high-intensity laser beams that vaporize or ablate the unwanted material, leaving behind a clean and restored surface. This technology has proven to be highly effective in removing dirt, rust, paint, graffiti, and other pollutants from various types of infrastructure.

Benefits of laser cleaning:

1. Preservation of historical and cultural heritage: Laser cleaning has revolutionized the preservation of historical and cultural structures. Traditional cleaning methods often involve the use of harsh chemicals or abrasive techniques that can damage delicate surfaces. Laser cleaning, on the other hand, allows for precise and controlled removal of contaminants without causing any harm to the underlying material. This makes it an ideal choice for cleaning and restoring ancient monuments, statues, and artworks.

2. Increased efficiency and cost-effectiveness: Laser cleaning offers significant advantages in terms of efficiency and cost-effectiveness. Unlike traditional cleaning methods that require extensive manual labor and time-consuming processes, laser cleaning can be automated and completed in a fraction of the time. This not only reduces labor costs but also minimizes downtime for infrastructure maintenance, resulting in substantial savings for both public and private sectors.

3. Environmental sustainability: Laser cleaning is an environmentally friendly technique as it eliminates the need for harsh chemicals and abrasive materials. Traditional cleaning methods often generate hazardous waste that can pollute the environment and pose health risks. Laser cleaning, however, produces minimal waste and does not release harmful substances into the air or water. This makes it a sustainable choice for infrastructure maintenance and preservation.

4. Versatility and adaptability: Laser cleaning technology is highly versatile and can be used on a wide range of surfaces, including concrete, metal, stone, and wood. It can effectively remove contaminants from intricate designs, crevices, and hard-to-reach areas, ensuring a thorough cleaning process. Moreover, laser cleaning can be adjusted to different power levels and frequencies, making it adaptable to various cleaning requirements.

Applications of laser cleaning in infrastructure maintenance:

1. Building facades: Laser cleaning can remove dirt, pollutants, and biological growth from building facades, restoring their original appearance and preventing further damage. It is particularly useful for cleaning delicate surfaces such as historical buildings or structures with intricate architectural details.

2. Bridges and tunnels: Laser cleaning can effectively remove rust, corrosion, and graffiti from bridges and tunnels, enhancing their structural integrity and aesthetics. It can also help in the maintenance of road signs and markings, ensuring clear visibility for drivers.

3. Monuments and statues: Laser cleaning is widely used for the preservation of monuments and statues, removing dirt, pollutants, and biological growth without causing any damage to the delicate surfaces. It helps in maintaining the visual appeal and historical significance of these structures.

4. Historical artifacts: Laser cleaning has revolutionized the restoration and preservation of historical artifacts. It can remove dirt, soot, and other contaminants from delicate objects such as paintings, manuscripts, and archaeological finds, ensuring their longevity and accessibility for future generations.

Keywords: laser cleaning, maintenance, preservation, infrastructure, non-contact, non-abrasive, contaminants, restoration, efficiency, cost-effectiveness, environmental sustainability, versatility, adaptability, building facades, bridges, tunnels, monuments, statues, historical artifacts.

Long-tail phrases: laser cleaning technology for infrastructure maintenance and preservation, benefits of laser cleaning in infrastructure maintenance, applications of laser cleaning in infrastructure maintenance and preservation.

The integration of laser cleaning technology into robotic systems

One of the key benefits of integrating laser cleaning technology into robotic systems is the ability to clean complex and hard-to-reach surfaces. Traditional cleaning methods often struggle to effectively clean intricate parts or components with intricate geometries. Laser cleaning, on the other hand, can easily access and clean areas that are difficult to reach manually or with other cleaning techniques. This makes it particularly suitable for industries such as aerospace, automotive, and electronics, where precision cleaning is crucial.

Moreover, laser cleaning technology offers a non-abrasive and non-destructive cleaning method. Unlike abrasive blasting, which can damage delicate surfaces or remove thin coatings, laser cleaning gently removes contaminants without causing any harm to the underlying material. This makes it ideal for cleaning sensitive components, such as electronic circuit boards or optical lenses, where preserving the integrity of the surface is essential.

In addition to its precision and non-destructive nature, laser cleaning technology is also environmentally friendly. Traditional cleaning methods often involve the use of harsh chemicals or generate hazardous waste, which can have detrimental effects on the environment and human health. Laser cleaning eliminates the need for chemicals and reduces waste generation, making it a sustainable and eco-friendly cleaning solution.

also offers significant time and cost savings. By automating the cleaning process, manufacturers can reduce labor costs and increase overall efficiency. Robotic systems equipped with laser cleaning technology can operate continuously, 24/7, without the need for breaks or rest, ensuring maximum productivity. Additionally, laser cleaning eliminates the need for consumables such as chemicals or abrasive materials, further reducing operational costs.

In conclusion, has revolutionized the way industries approach surface cleaning and restoration processes. This technology offers precision, efficiency, and environmental friendliness, making it an ideal solution for various industries. By combining the capabilities of robotics and laser cleaning, manufacturers can achieve consistent and high-quality cleaning results while reducing costs and improving productivity.

Keywords: laser cleaning technology, robotic systems, integration, surface cleaning, restoration processes, precision, efficiency, environmental friendliness, non-contact method, contaminants, coatings, oxides, traditional cleaning methods, chemical cleaning, abrasive blasting, productivity, quality control, complex surfaces, hard-to-reach surfaces, aerospace industry, automotive industry, electronics industry, non-abrasive, non-destructive, delicate surfaces, environmentally friendly, sustainable, time savings, cost savings, labor costs, operational costs.

Long-tail phrases:

– Laser cleaning technology in industrial applications

– Benefits of laser cleaning in robotic systems

– Precision cleaning with laser technology

– Non-abrasive and non-destructive cleaning methods

– Environmental advantages of laser cleaning

– Time and cost savings with laser cleaning in robotics

The role of laser cleaning in the removal of contaminants from electronic components

Laser cleaning is a non-contact, non-abrasive, and environmentally friendly method of removing contaminants from surfaces. It involves the use of high-intensity laser beams to vaporize or ablate the contaminants without damaging the underlying material. The laser beam is focused on the contaminated area, and the energy from the laser causes the contaminants to evaporate or disintegrate, leaving behind a clean surface. This technology is highly precise and can remove contaminants from even the most intricate and delicate electronic components.

Advantages of laser cleaning in electronic component cleaning:

1. Non-destructive: Laser cleaning is a non-destructive method, which means it does not damage the electronic components. It selectively removes only the contaminants without affecting the surface or structure of the components. This is particularly important for delicate and sensitive electronic components.

2. High precision: Laser cleaning offers high precision cleaning, allowing for the removal of contaminants from even the smallest and most intricate areas. The laser beam can be focused to a very small spot size, enabling precise cleaning without causing any damage.

3. Versatility: Laser cleaning can be used to remove a wide range of contaminants from electronic components. It can effectively remove dust, dirt, oils, greases, oxides, adhesives, and other organic and inorganic substances. This versatility makes laser cleaning suitable for various industries and applications.

4. Efficiency: Laser cleaning is a highly efficient method of cleaning electronic components. It can remove contaminants quickly and effectively, reducing the cleaning time and improving productivity. Additionally, laser cleaning does not require any chemicals or solvents, eliminating the need for manual scrubbing or harsh cleaning agents.

5. Environmentally friendly: Laser cleaning is an environmentally friendly cleaning method. It does not produce any hazardous waste or emissions, making it a sustainable and green cleaning solution. This is particularly important in industries where environmental regulations are stringent.

Applications of laser cleaning in electronic component cleaning:

Laser cleaning technology has found widespread applications in the cleaning of electronic components. Some of the key applications include:

1. Printed circuit boards (PCBs): Laser cleaning is used to remove flux residues, soldering residues, and other contaminants from PCBs. It ensures the reliability and functionality of the PCBs by eliminating any potential short circuits or corrosion.

2. Semiconductor devices: Laser cleaning is used in the manufacturing and maintenance of semiconductor devices. It removes particles, oxides, and other contaminants from the surfaces of semiconductor wafers, improving their performance and yield.

3. Optics and lenses: Laser cleaning is used to clean optical components such as lenses, mirrors, and prisms. It removes dust, fingerprints, and other contaminants, ensuring optimal performance and clarity.

4. Connectors and contacts: Laser cleaning is used to clean connectors and contacts in electronic devices. It removes oxidation, dirt, and other contaminants, ensuring reliable electrical connections.

5. Display panels: Laser cleaning is used to clean display panels, such as LCDs and OLEDs. It removes fingerprints, smudges, and other contaminants, improving the visual quality and longevity of the displays.

Keywords: laser cleaning, electronic components, contaminants, non-destructive, high precision, versatility, efficiency, environmentally friendly, printed circuit boards, semiconductor devices, optics, connectors, display panels.

Long-tail phrases: role of laser cleaning in removing contaminants from electronic components, advantages of laser cleaning in electronic component cleaning, applications of laser cleaning in electronic component cleaning.

The potential for laser cleaning to reduce the risk of cross-contamination in the healthcare sector

One of the main advantages of laser cleaning is its ability to reach areas that are difficult to clean using traditional methods. In healthcare facilities, there are numerous hard-to-reach surfaces, such as crevices, corners, and intricate medical equipment. These areas can harbor pathogens and pose a significant risk of cross-contamination. Laser cleaning can effectively clean these surfaces, ensuring that no contaminants remain hidden.

Furthermore, laser cleaning is a chemical-free process, eliminating the need for harsh cleaning agents that may leave behind toxic residues. Traditional cleaning methods often rely on chemicals such as bleach or disinfectants, which can be harmful to both patients and healthcare workers. Laser cleaning provides a safer alternative by using only focused laser beams to achieve cleanliness. This reduces the risk of chemical exposure and associated health hazards.

Another advantage of laser cleaning is its ability to disinfect surfaces. The high-energy laser pulses can effectively kill bacteria, viruses, and other pathogens, reducing the risk of cross-contamination. Traditional cleaning methods may not always achieve the same level of disinfection, especially in hard-to-reach areas. Laser cleaning ensures that all surfaces are thoroughly disinfected, providing a safer environment for patients and healthcare workers.

Additionally, laser cleaning is a time-efficient process. Traditional cleaning methods often require significant time and effort to achieve the desired level of cleanliness. In healthcare settings, where time is of the essence, laser cleaning can significantly reduce cleaning time. The precise and rapid action of laser beams allows for quick and efficient cleaning, enabling healthcare facilities to maintain high standards of cleanliness without compromising productivity.

In conclusion, laser cleaning has the potential to revolutionize the healthcare sector by reducing the risk of cross-contamination. Its ability to reach difficult-to-clean areas, chemical-free operation, disinfection capabilities, and time efficiency make it an ideal solution for healthcare facilities. By implementing laser cleaning technology, healthcare providers can enhance patient safety, protect healthcare workers, and maintain a clean and hygienic environment.

Keywords: laser cleaning, cross-contamination, healthcare sector, microorganisms, pathogens, infections, diseases, cleaning protocols, emerging technology, non-contact, non-abrasive, contaminants, vaporize, disintegrate, cleanliness, hard-to-reach surfaces, medical equipment, chemical-free, toxic residues, bleach, disinfectants, chemical exposure, health hazards, disinfection, bacteria, viruses, time-efficient, productivity, patient safety, hygienic environment.

Long-tail phrases: laser cleaning technology in healthcare, reducing cross-contamination in healthcare, benefits of laser cleaning in healthcare, laser cleaning for disinfection, laser cleaning for hard-to-reach surfaces, chemical-free cleaning in healthcare, time-efficient cleaning in healthcare.

- Laser cleaning for removing contaminants from ceramics - 25 April 2024

- Internet education platform - 25 April 2024

- The future prospects of laser cleaning technology - 6 February 2024