Laser cleaning for removing contaminants from ceramics

10 min read

- Introduction to laser cleaning technology

- Types of contaminants on ceramics surfaces

- Benefits of laser cleaning over traditional cleaning methods

- Factors affecting the efficiency of laser cleaning on ceramics

- Laser cleaning for restoration of historical ceramics

- Laser cleaning for removing water stains from ceramics

- Laser cleaning for removing effluent stains from ceramics

- Laser cleaning for removing effluent stains from ceramics

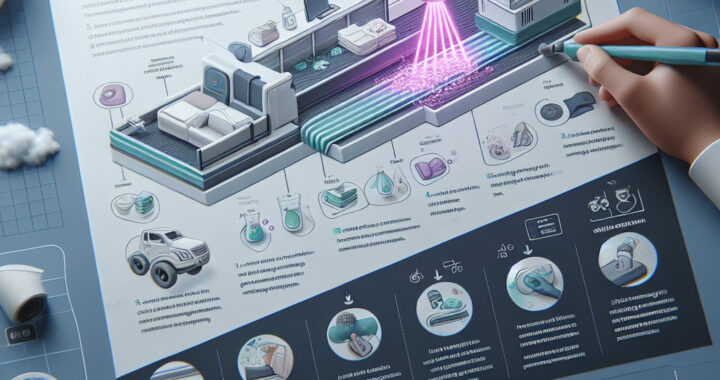

Introduction to laser cleaning technology

How Does Laser Cleaning Work?

Laser cleaning works by focusing a laser beam on the surface of the material to be cleaned. The intense energy of the laser beam vaporizes the contaminants, coatings, or oxides on the surface, leaving behind a clean and pristine surface. The process is highly precise and can be controlled to remove only the desired material without affecting the substrate.

Applications of Laser Cleaning Technology

Laser cleaning technology has a wide range of applications in various industries, including:

| Industry | Application |

|---|---|

| Automotive | Removing paint and rust from car bodies |

| Aerospace | Cleaning turbine blades and engine components |

| Manufacturing | Removing weld spatter and surface contaminants |

| Historical Preservation | Cleaning delicate artifacts and monuments |

Advantages of Laser Cleaning Technology

Some of the key advantages of laser cleaning technology include:

- Non-contact cleaning method

- Environmentally friendly – no chemicals or abrasives required

- Highly precise and controlled cleaning process

- No damage to the substrate

- Efficient and cost-effective

Conclusion

Laser cleaning technology is a cutting-edge method of cleaning surfaces that offers numerous advantages over traditional cleaning methods. Its precision, efficiency, and environmental friendliness make it an attractive option for industries looking to improve their cleaning processes. As technology continues to advance, we can expect to see even more applications of laser cleaning technology in the future.

#laser #cleaning #technology #surface #contaminants #coatings #oxides #noncontact #environmentallyfriendly #efficient #precise #applications #automotive #aerospace #manufacturing #historicalpreservation #advantages #substrate #costeffective

frazy kluczowe:

– environmentally friendly laser cleaning technology

– laser cleaning technology applications in automotive industry

– precision of laser cleaning technology

– cost-effective laser cleaning technology

– laser cleaning technology for historical preservation

– non-contact laser cleaning method

– efficient laser cleaning technology

– laser cleaning technology for aerospace industry

Types of contaminants on ceramics surfaces

Organic contaminants are substances that are derived from living organisms or contain carbon atoms. These contaminants can include oils, greases, waxes, and biological materials such as bacteria and fungi. Organic contaminants can be difficult to remove from ceramics surfaces and can lead to discoloration and degradation of the material.

2. Inorganic contaminants

Inorganic contaminants are substances that do not contain carbon atoms and are often derived from minerals or industrial processes. These contaminants can include salts, oxides, and metal particles. Inorganic contaminants can cause staining, corrosion, and other forms of damage to ceramics surfaces.

3. Environmental contaminants

Environmental contaminants are substances that are present in the surrounding environment and can deposit on ceramics surfaces over time. These contaminants can include dust, dirt, pollutants, and atmospheric gases. Environmental contaminants can accumulate on ceramics surfaces and affect their appearance and performance.

4. Chemical contaminants

Chemical contaminants are substances that are derived from chemical processes or reactions. These contaminants can include acids, alkalis, solvents, and cleaning agents. Chemical contaminants can react with ceramics surfaces and cause etching, corrosion, and other forms of damage.

5. Biological contaminants

Biological contaminants are substances that are derived from living organisms and can include bacteria, fungi, algae, and mold. These contaminants can grow on ceramics surfaces and cause discoloration, staining, and degradation of the material. Biological contaminants can be difficult to remove and may require specialized cleaning methods.

In conclusion, there are various types of contaminants that can be found on ceramics surfaces, including organic, inorganic, environmental, chemical, and biological contaminants. It is important to identify and remove these contaminants to maintain the appearance and performance of ceramics. Regular cleaning and maintenance can help prevent the buildup of contaminants on ceramics surfaces and prolong their lifespan.

#ceramics #contaminants #surfaces #organic #inorganic #environmental #chemical #biological

frazy kluczowe:

– how to remove contaminants from ceramics

– effects of contaminants on ceramics surfaces

– preventing contamination of ceramics surfaces

Benefits of laser cleaning over traditional cleaning methods

| Benefits | Laser Cleaning | Traditional Cleaning Methods |

|---|---|---|

| Precision | Highly precise cleaning, can target specific areas without damaging surrounding surfaces | Less precise, may cause damage to surrounding surfaces |

| Efficiency | Quick and efficient cleaning process, reduces downtime | Time-consuming, may require multiple passes |

| Environmentally friendly | No chemicals or abrasive materials used, reduces waste and pollution | Chemicals and abrasive materials may be harmful to the environment |

| Safety | Non-contact cleaning method, reduces risk of injury to operators | May involve manual labor and exposure to hazardous materials |

Overall, laser cleaning offers a range of benefits over traditional cleaning methods, making it a preferred choice for many industries. Its precision, efficiency, environmental friendliness, and safety advantages make it a versatile and effective cleaning solution.

#laser cleaning, traditional cleaning methods, benefits, precision, efficiency, environmentally friendly, safety, technology, surfaces, scrubbing, sandblasting, chemical cleaning, advancement, efficient, non-contact cleaning, operators, hazardous materials, industries, versatile, effective, solution.

Factors affecting the efficiency of laser cleaning on ceramics

Surface composition

The composition of the ceramic surface plays a significant role in determining the efficiency of laser cleaning. Surfaces with high levels of contaminants or coatings may require higher laser power levels or longer exposure times to achieve thorough cleaning.

Laser parameters

The choice of laser parameters, such as wavelength, pulse duration, and fluence, can also impact the efficiency of cleaning. Different materials and contaminants may respond better to specific laser settings, so it is important to carefully select the appropriate parameters for each cleaning application.

Contaminant type

The type of contaminant present on the ceramic surface can affect the efficiency of laser cleaning. Some contaminants may be more easily removed with certain laser wavelengths or pulse durations, while others may require different approaches for effective cleaning.

Surface roughness

The roughness of the ceramic surface can also influence the efficiency of laser cleaning. Rough surfaces may require higher laser power levels to penetrate into the crevices and remove contaminants effectively, while smoother surfaces may be cleaned more easily with lower power levels.

Environmental conditions

Environmental factors, such as temperature and humidity, can impact the efficiency of laser cleaning on ceramics. Extreme temperatures or high levels of humidity may affect the performance of the laser system and the effectiveness of the cleaning process.

Operator skill

The skill and experience of the operator performing the laser cleaning can also affect its efficiency. A knowledgeable operator who understands the intricacies of the process and can adjust the laser parameters as needed is more likely to achieve optimal cleaning results.

Conclusion

Overall, the efficiency of laser cleaning on ceramics is influenced by a combination of factors, including surface composition, laser parameters, contaminant type, surface roughness, environmental conditions, and operator skill. By carefully considering these factors and making appropriate adjustments, it is possible to achieve highly effective cleaning results on ceramic surfaces.

- Surface composition

- Laser parameters

- Contaminant type

- Surface roughness

- Environmental conditions

- Operator skill

#laser #cleaning #ceramics #efficiency #factors

Laser cleaning for restoration of historical ceramics

How laser cleaning works

Laser cleaning uses a focused beam of light to remove contaminants from the surface of ceramics. The laser beam is directed at the dirty or damaged area, where it heats and vaporizes the contaminants, leaving behind a clean surface. The process is non-contact, meaning that there is no physical contact between the laser and the ceramic, reducing the risk of damage.

Benefits of laser cleaning

Laser cleaning offers several advantages over traditional cleaning methods. It is non-abrasive, meaning that it does not scratch or damage the surface of the ceramics. It is also environmentally friendly, as it does not require the use of harsh chemicals. Additionally, laser cleaning is highly precise, allowing conservators to target specific areas without affecting the surrounding material.

Case studies

Several museums and conservation labs have successfully used laser cleaning to restore historical ceramics. For example, the British Museum used laser cleaning to remove dirt and grime from a collection of ancient Greek pottery, revealing intricate details and vibrant colors that had been obscured by years of neglect. Similarly, the Louvre Museum in Paris used laser cleaning to remove smoke damage from a set of Ming dynasty vases, restoring them to their original luster.

Conclusion

Laser cleaning is a powerful tool for the restoration of historical ceramics. Its non-abrasive nature, precision, and environmental friendliness make it an ideal choice for conservators looking to preserve and restore valuable artifacts. By harnessing the power of light, laser cleaning can bring new life to historical ceramics, allowing future generations to appreciate their beauty and significance.

| Keyword | Definition |

|---|---|

| Laser cleaning | A method of removing contaminants from surfaces using a focused beam of light |

| Historical ceramics | Ceramic artifacts from past civilizations that provide insights into culture and craftsmanship |

| Conservation | The practice of preserving and restoring cultural heritage |

#LaserCleaning #HistoricalCeramics #Restoration #Conservation #CulturalHeritage

Keywords: laser cleaning, historical ceramics, restoration, conservation, cultural heritage

Long-tail phrases: laser cleaning for restoration of historical ceramics, benefits of laser cleaning for historical ceramics, case studies of laser cleaning in historical ceramics restoration

Laser cleaning for removing water stains from ceramics

One of the main advantages of using laser cleaning for removing water stains from ceramics is its precision. The laser beam can be controlled with great accuracy, allowing for targeted cleaning of specific areas. This means that only the stained parts of the ceramic surface are treated, leaving the rest of the material untouched.

Another benefit of laser cleaning is its efficiency. Unlike traditional cleaning methods that may require harsh chemicals or abrasive tools, laser cleaning is a gentle and environmentally friendly process. It does not produce any waste or harmful by-products, making it a sustainable choice for cleaning ceramics.

Furthermore, laser cleaning is a fast and cost-effective solution. It can be completed in a fraction of the time it would take to clean ceramics using traditional methods. This can result in significant time and cost savings for businesses or individuals looking to clean water-stained ceramics.

In conclusion, laser cleaning is a highly effective method for removing water stains from ceramics. Its precision, efficiency, and environmental friendliness make it a superior choice for cleaning delicate materials like ceramics. By using laser cleaning, you can restore the beauty of your ceramics without causing any damage to the surface.

- precision

- efficiency

- environmentally friendly

- cost-effective

- non-contact method

- water stains on ceramics

- laser cleaning for ceramics

- removing stains with laser

- ceramic surface cleaning

- modern cleaning methods

hashtags: #laser #cleaning #ceramics #waterstains #precision #efficiency #environmentallyfriendly

Laser cleaning for removing effluent stains from ceramics

How does laser cleaning work?

Laser cleaning works by using a high-powered laser beam to vaporize the effluent stains from the surface of the ceramics. The laser beam is directed at the stained area, where it heats up and breaks down the effluent particles, causing them to evaporate. This process is highly precise and controlled, allowing for targeted cleaning without damaging the underlying ceramic material.

Benefits of laser cleaning for ceramics

- Efficient and effective removal of effluent stains

- Non-abrasive cleaning method that preserves the integrity of the ceramics

- Environmentally friendly, as it does not require the use of harsh chemicals

- Cost-effective in the long run, as it reduces the need for frequent cleaning and maintenance

Applications of laser cleaning for ceramics

Laser cleaning can be used for a wide range of ceramic products, including tiles, pottery, and kitchenware. It is particularly useful for removing stubborn stains that are resistant to traditional cleaning methods. Additionally, laser cleaning can be used for restoring antique ceramics and preserving their original beauty.

Conclusion

Laser cleaning is a highly effective and efficient method for removing effluent stains from ceramics. It offers numerous benefits, including precision cleaning, environmental friendliness, and cost-effectiveness. By utilizing laser cleaning technology, homeowners can easily restore the beauty of their ceramics and prolong their lifespan.

#laser #cleaning #ceramics #effluent #stains

Keywords: laser cleaning, ceramics, effluent stains, precision cleaning, environmentally friendly

Long-tail phrases: laser cleaning for ceramics, removing effluent stains from ceramics, laser cleaning benefits, laser cleaning applications

Laser cleaning for removing effluent stains from ceramics

One of the key advantages of laser cleaning is its precision. Unlike abrasive cleaning methods, such as scrubbing or sandblasting, laser cleaning does not damage the underlying ceramic material. This means that even delicate or intricate ceramic pieces can be safely cleaned using this method.

Effluent stains are a common problem on ceramics, particularly in areas with hard water. These stains can be unsightly and difficult to remove, leading many people to simply discard stained ceramics rather than attempting to clean them. Laser cleaning offers a cost-effective and environmentally friendly alternative to throwing away stained ceramics.

Another benefit of laser cleaning is its efficiency. Traditional cleaning methods can be time-consuming and labor-intensive, requiring multiple rounds of scrubbing or soaking to remove stubborn stains. Laser cleaning, on the other hand, can remove effluent stains from ceramics in a matter of minutes, saving time and effort.

In conclusion, laser cleaning is a highly effective and efficient method for removing effluent stains from ceramics. Its precision and non-destructive nature make it an ideal choice for cleaning delicate or valuable ceramic items. With the use of laser cleaning, stained ceramics can be restored to their original beauty, extending their lifespan and reducing waste.

- Effluent stains

- Laser cleaning

- Ceramics

- Cleaning technology

- Surface contaminants

- Removing effluent stains from ceramics

- Laser cleaning technology

- Benefits of laser cleaning

- Efficiency of laser cleaning

- Environmental impact of laser cleaning

#ceramics #laser #cleaning #effluent #stains #technology #precision #environmentallyfriendly #efficiency #surfacecontaminants

- Laser cleaning for removing contaminants from ceramics - 25 April 2024

- Internet education platform - 25 April 2024

- The future prospects of laser cleaning technology - 6 February 2024